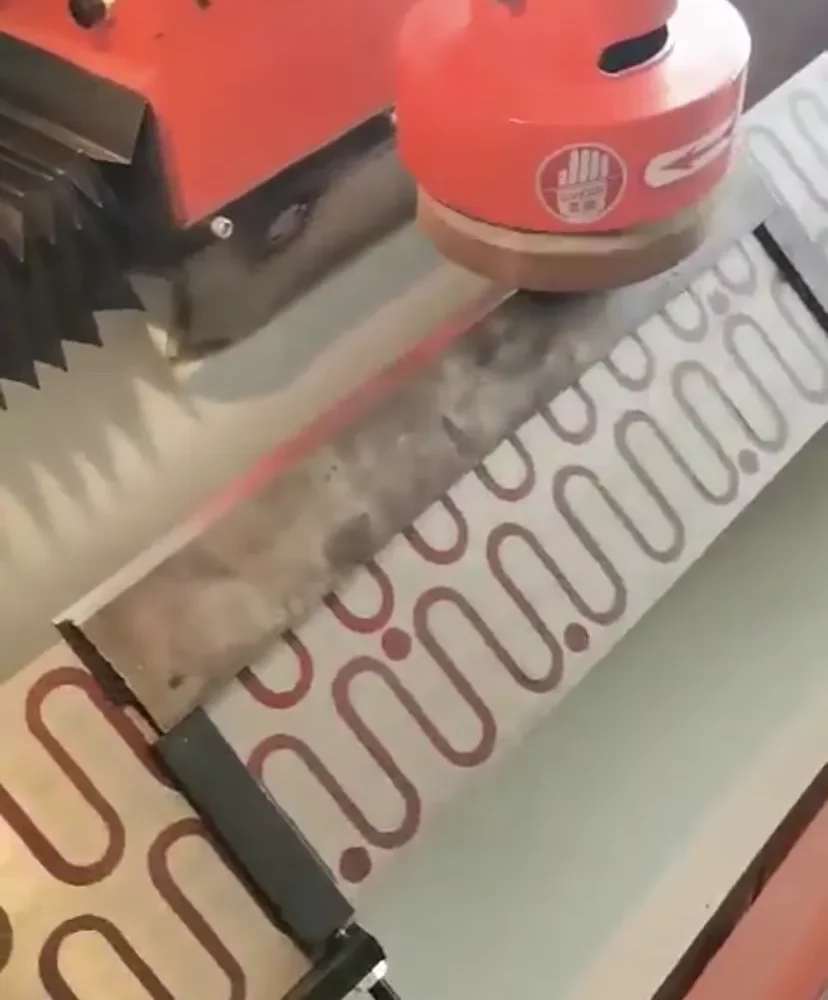

MF2510CNC-paper cutting blade sharpening machine

Brief Description

The lightweight linear sharpening machine is a professional equipment that focuses on grinding various types of straight edge cutting tools, especially rotary cutters, woodworking planers, paper cutters, etc.It can flexibly choose the appropriate model according to the actual length of the tool, and supports grinding and processing of up to 1500mm specification tools.

It is widely suitable for various fields such as wood processing, printing and packaging, furniture manufacturing, etc

The compact cantilever body structure and program can achieve low grinding volume and high efficiency in machining. After grinding, the cutting edge is sharp and the straightness is excellent.

The compact cantilever body structure and program can achieve low grinding volume and high efficiency in machining. After grinding, the cutting edge is sharp and the straightness is excellent.

Its worktable supports 0~± 90 ° rotation adjustment, which can accurately match the grinding angle requirements of different tools. Paired with a mechanical tool holder or electromagnetic suction cup fixing device, it can firmly clamp tools of different lengths, even for 1500mm long blade tools, it can be stably fixed to avoid displacement affecting accuracy during grinding.

This machine is specially designed for sharpening straight knives on both the flat surface and the back edge. Sharpening is performed automatically with the use of coolant.

MF2510CNC straight knife sharpening machine, suitable for grinding straight knives below 1500mm.

Equipped with electromagnetic suction cups

paper cutting blade sharpening machine The cooling system and angle adjuster are fixed and stable, with temperature control and knife protection, and the angle is flexible and adjustable.The intelligent touch screen is easy to operate, supports one click switching between fine grinding/coarse grinding, and is equipped with automatic cutting function,No need for frequent manual intervention, efficiently and accurately adapting to the needs of multiple industries for straight edge machining.

paper cutting blade sharpening machine The machine is recommended for furniture and joinery manufacturers that utilize planer, jointer and four-sided moulder machines.

TYPES OF SHARPENABLE TOOLS:

Machine Video:

Specifications

| Item | Value |

|---|---|

| Model | MF2510 CNC |

| Maximum Processing Length, mm | 1500 |

| Maximum Knife Width, mm | 160 |

| Minimum Material Removal per Pass, mm | 0.002 |

| Maximum Material Removal per Pass, mm | 0.01 |

| Grinding Wheel Size, mm | 32×50×150 |

| Grinding Wheel Rotation Speed, rpm | 2830 |

| Coolant Pump Power, W | 40 |

| Feed Motor Power, W | 120 |

| Main Motor Power, kW | 7.5 |

| Overall Dimensions, mm | 3350×1130×1850 |

Structural Features:

Translation

CAST MACHINE BED

The machine is built on the basis of a cast machine bed. Only a cast machine bed can provide the required rigidity, vibration resistance and machine reliability, thus ensuring high-precision tool sharpening.

Terminology Notes

Translation

CARRIAGE WITH SHARPENING UNIT

The carriage with sharpening unit moves automatically by means of an electric drive. The machine adopts HIWIN linear guides (Taiwan). This ensures precise movement and smooth travel of the sharpening unit during the sharpening process.

TOUCH CONTROL PANEL

The touch control panel ensures ease of operation, and allows setting the material removal per pass and adjusting the carriage travel speed.

ELECTROMAGNETIC PLATE

The electromagnetic plate is made of high-quality steel, enabling the clamping of flat knives made of HSS and DS steel.

AUTOMATIC LUBRICATION SYSTEM

Centralized lubrication system for machine components. It enables lubricant to be delivered to all linear guides in the shortest possible time. The worktable is lubricated by an independent pump.