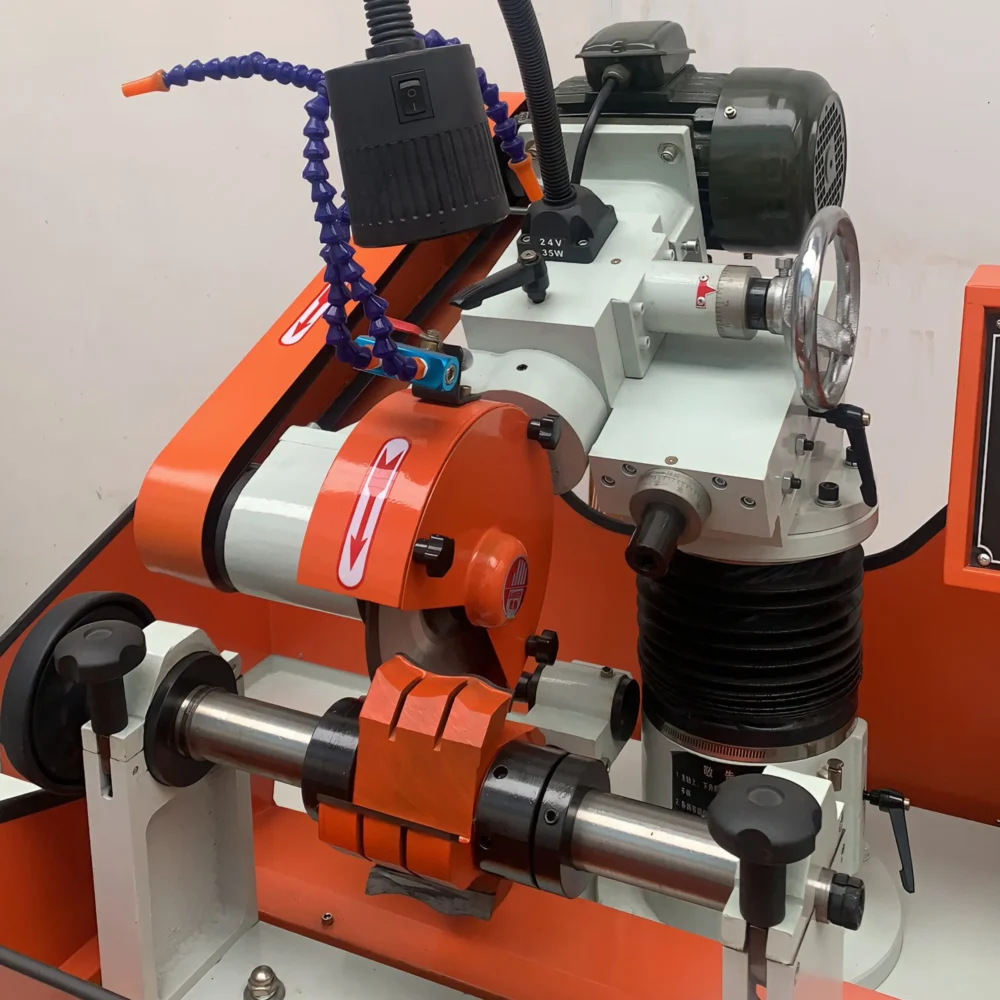

MF223C-cutter sharpening machine

Brief Description

MF223C imitation grinding machine is suitable for the grinding needs of various types of cutting tools such as curved cutting tools and milling cutters. equipmentEquipped with high-precision scale rings and precision guide rails, ensuring precise and controllable grinding trajectory, and excellent consistency in blade angleDifferent. Equipped with multiple specifications of tool shafts, it can flexibly match the machining needs of different sizes of cutting tools, and can be paired with grinding wheels for complete assembly.It can continuously maintain grinding accuracy and blade smoothness. Built in frequency converter, can be adjusted according to the material of the cutting tool With grinding technology, stepless speed adjustment, compact overall structure design, convenient and efficient operation

MF223C Copy grinding machine.

The Woodworking Special-Shaped Cutting Tool Imitation Sharpening Machine: Precision Grinding via Master Mold Replication

TYPES OF TOOLS TO BE SHARPENED:

Specifications

| Parameter | Value |

|---|---|

| Model | MF223C |

| Max. End Mill Diameter, mm | 355 |

| Max. End Mill Height, mm | 300 |

| Diamond Grinding Wheel Size, mm | 255×60 |

| Grinding Wheel Rotation Speed, rpm | 0–10000 |

| Motor Power, kW | 2.2 |

| Supply Voltage, V | 380 |

| Overall Machine Dimensions, mm | 1350×1130×1600 |

| Weight, kg | 750 |

Constructive Features:

For ease of operation, the machine is supplied with 4 arbors for the tools to be sharpened. Arbor replacement is convenient and does not take much time.

The machine is equipped with a grinding wheel profiling fixture that enables shaping the wheel to the required profile and thickness, as well as eliminating axial and radial runout.

The fixture for manual sharpening of end mills and drills consists of an indexing head with a clamping collet chuck. This fixture enables the sharpening of end mills.

The variable frequency drive (VFD) for stepless speed adjustment (0–10,000 rpm) of the grinding wheel ensures quick machine retooling for both rough and finish grinding operations.

Thanks to the grinding wheel clamping system with flanges, constant wheel truing is not required, which increases machine productivity and ensures optimal sharpening quality.

The high-precision linear guides are made of durable, wear-resistant steel. They ensure smooth movement of the worktable and, consequently, high sharpening accuracy (the linearity deviation of the worktable is ±0.005 mm per meter).