High Precision Planer Blade Grinding Machine – Automatic Straight Knife Sharpening Equipment

Product Overview – Automatic Straight Knife Sharpening Machines

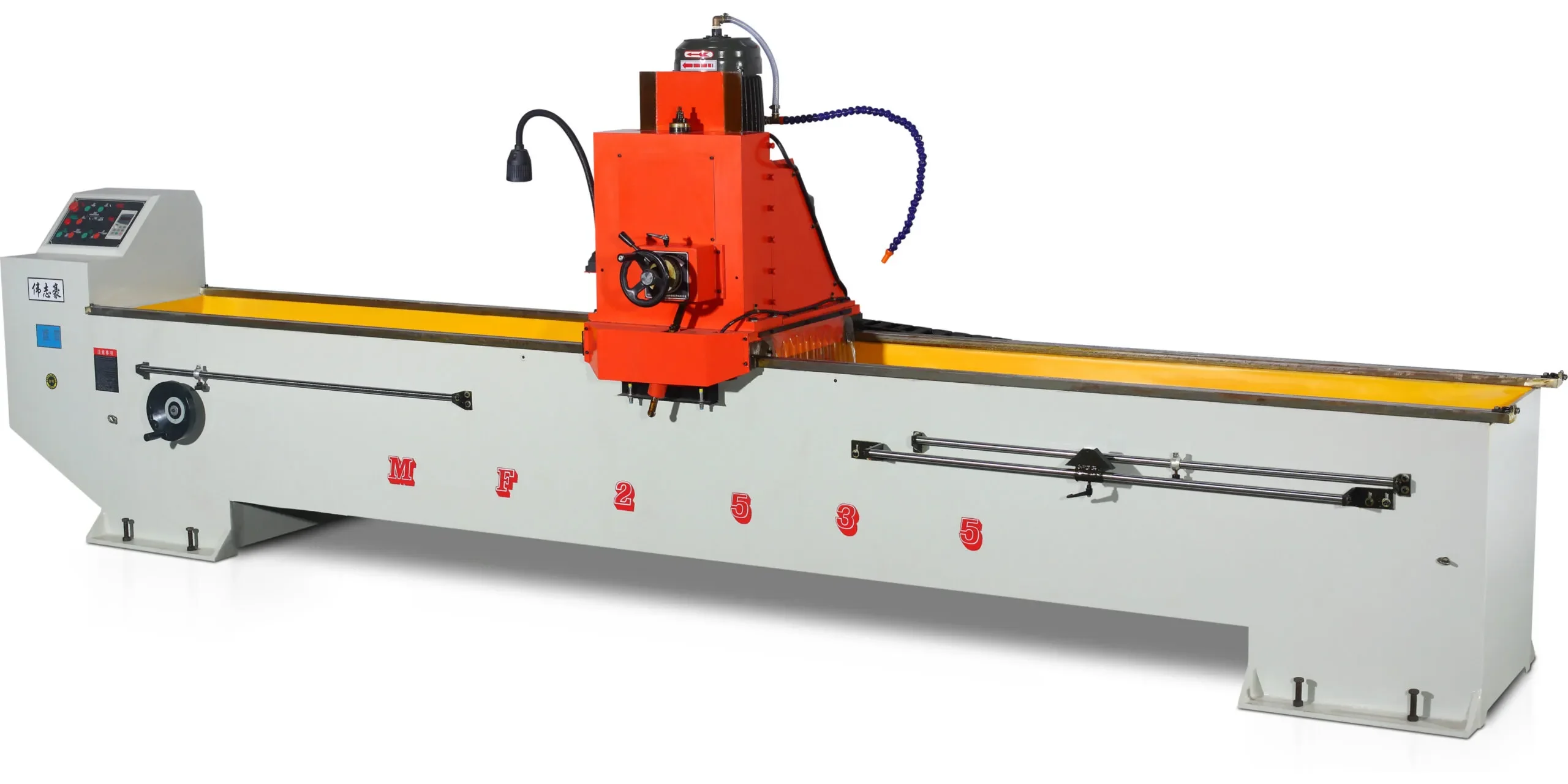

High Precision Planer Blade Grinding Machine for Woodworking

This high precision planer blade grinding machine for woodworking is specially designed for sharpening straight knives on both the flat surface and the back edge. Sharpening is carried out automatically with coolant, ensuring consistent sharpness and protecting the blade from overheating during processing.

Heavy Duty Planer Blade Grinding Machine with Water Cooling

The heavy duty planer blade grinding machine with water cooling, a robust variant of straight knife grinding equipment, is designed specifically for grinding ultra-long straight knives. Its core configuration includes powerful electromagnetic suction cups that provide even and strong suction to firmly fix the long knife without displacement.

Specifications

Detailed technical parameters of the high precision planer blade grinding machine, including dimensions, grinding range, power, and cooling system specifications, are listed below to facilitate equipment selection and matching with production lines.

Specifications:

| Parameter | Value |

|---|

| Model | MF-2520 |

| Maximum Processing Length, mm | 2000 |

| Maximum Knife Width, mm | 160 |

| Carriage Feed Speed, m/min | 3–12 |

| Table Rotation Angle, ° | -90° – +90° |

| Grinding Wheel Size, mm | 32×50×150 |

| Grinding Wheel Rotation Speed, rpm | 2,830 |

| Coolant Pump Power, W | 40 |

| Feed Motor Power, kW | 0.75 |

| Main Motor Power, kW | 7.5 |

| Overall Dimensions, mm | 4200×1200×1850 |

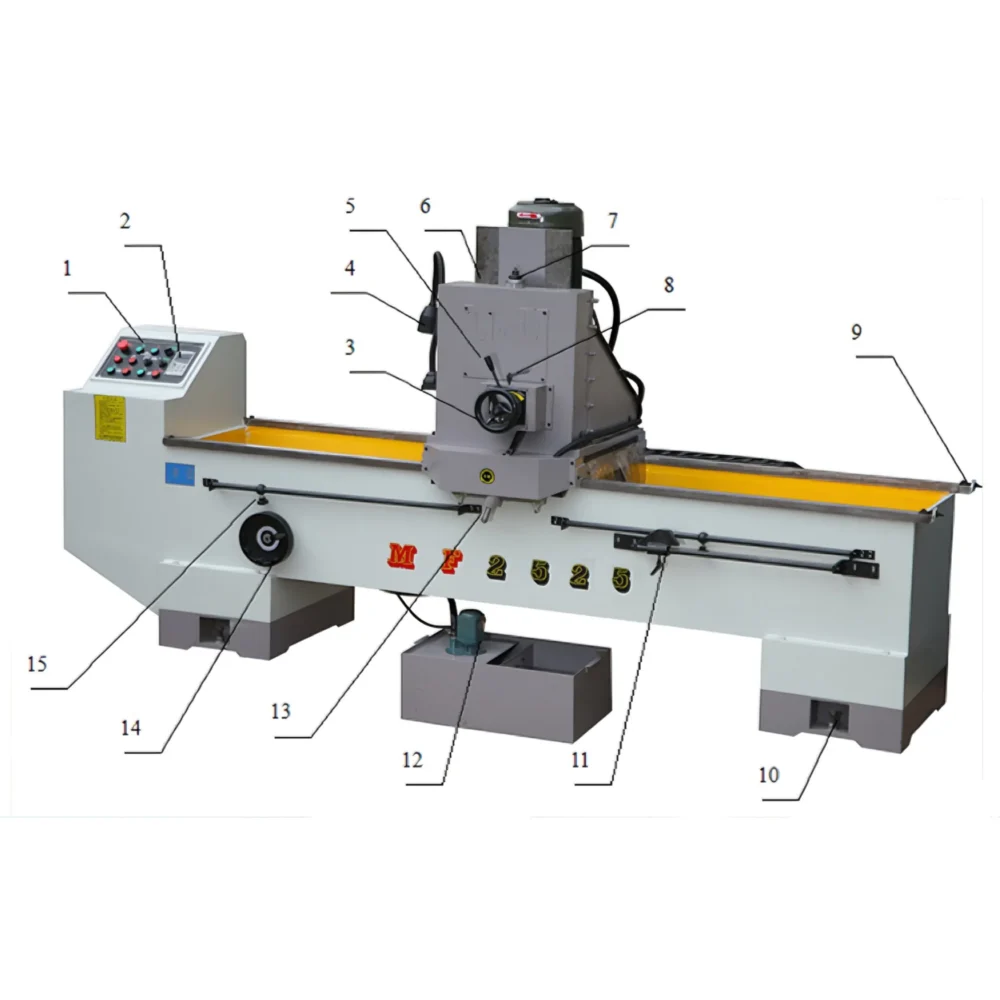

Constructive Features:

CAST BED

The machine is built on the basis of a cast bed. Only a cast bed can provide the machine with the necessary rigidity, vibration resistance and reliability, thus guaranteeing high-precision tool sharpening.

CARRIAGE WITH SHARPENING UNIT

The carriage with sharpening unit moves in automatic mode by means of an electric drive. The machine adopts HIWIN (Taiwan) linear guides. This ensures precise movement and smooth operation of the sharpening unit during the sharpening process.

CENTRALIZED LUBRICATION SYSTEM

Centralized lubrication system for machine components. It enables lubricant to be delivered to all linear guides in the shortest possible time. The worktable is lubricated by an independent pump.

TOUCH CONTROL PANEL

The touch control panel ensures ease of operation, and allows setting the depth of cut per pass as well as adjusting the carriage feed speed.

Core Structure & Operational Advantages

Gantry Design & Precision Transmission System

The equipment adopts a gantry style body and gear rack transmission, combined with a water-cooled grinding head and a precise speed control system. This combination enables smooth and efficient grinding, meeting the high standards of industrial blade processing.

User-Friendly Electromagnetic Suction Cup

The electromagnetic suction cup is easy to operate, supporting fast charging and demagnetization. It also features delayed demagnetization protection, which can avoid deformation of the long knife and ensure the precision of blade grinding— a key advantage for both planer blades and cutter blades.

Industrial Applications & Matching Equipment

Suitable for Furniture & Carpentry Manufacturers

It is highly recommended for furniture and carpentry manufacturers that operate thicknessers, jointers and four-sided planers. These enterprises can pair it with the high efficiency cutter blade sharpening machine for workshop to cover all straight knife sharpening needs.

Industrial Chipper Blade Sharpening Machine for Hardwood

For manufacturers dealing with hardwood processing, the industrial chipper blade sharpening machine for hardwood complements this planer blade grinding equipment. It provides targeted sharpening solutions for chipper blades, expanding the equipment portfolio for comprehensive woodworking production.

Supporting Technology & Versatility

Automatic Chipper Blade Sharpening Machine with Angle Adjustment

Similar to the automatic operation of this planer blade grinding machine, the automatic chipper blade sharpening machine with angle adjustment adopts automated processes with coolant, ensuring efficient and precise sharpening for curved and straight chipper blades alike.

Multi-Functional Cutter Blade Sharpening Machine for Metal Processing

While focusing on woodworking straight knives, this equipment’s precision grinding technology is also aligned with the multi-functional cutter blade sharpening machine for metal processing. Both prioritize stability and accuracy to meet diverse industrial blade maintenance demands.