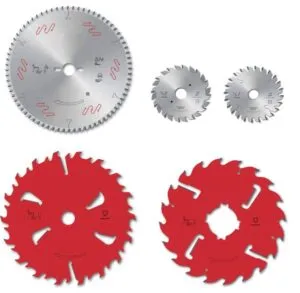

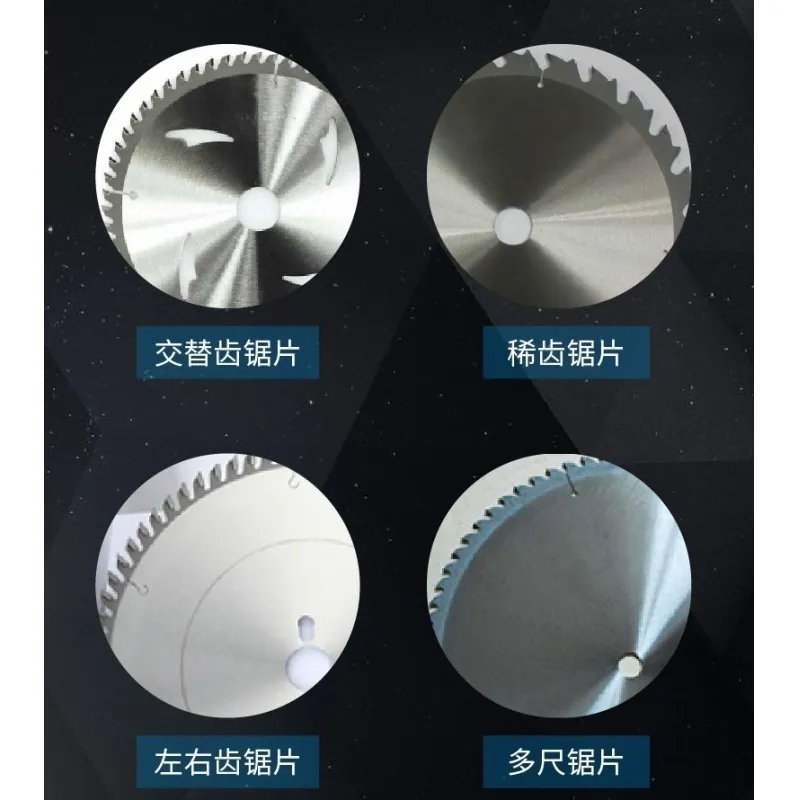

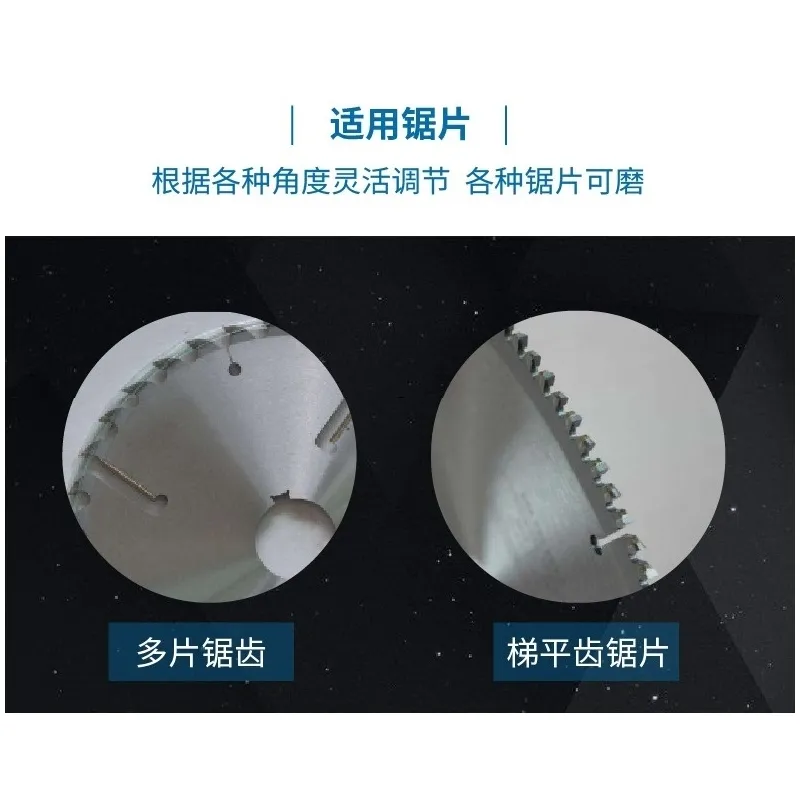

1.1 Designed for Brazed Teeth Circular Saw Blade Sharpening

The MF128 is customized for circular saw blades with brazed teeth, which are widely used in multi-material processing. Its structural design fully adapts to the characteristics of brazed teeth, avoiding damage to the blade body and brazing joints during grinding, while ensuring the sharpness and flatness of each tooth tip, effectively extending the service life of saw blades.

1.2 Wide Application in Woodworking, Metalworking & Polymer/Plastics Processing

With strong material compatibility, the MF128 is widely applicable to saw blades used in woodworking, metalworking, and polymer/plastic processing industries. It can flexibly adapt to the processing needs of different material saw blades, realizing one machine for multiple uses and greatly improving equipment utilization for enterprises of all sizes.

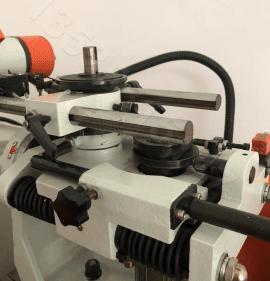

Core Features: Transverse Grinding & 180° Angle Rotation of MF128 Saw Sharpener

The MF128 adheres to the design concept of “stability first, efficiency improvement”, and its core features are closely combined with actual production needs, solving the pain points of long adjustment time, low precision, and single function of traditional grinding equipment.

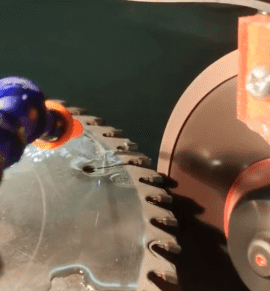

2.1 Transverse Grinding Design with Horizontal Spindle Layout

The MF128 circular saw blade grinding machine adopts a transverse grinding design, matched with a horizontal spindle layout. This structure effectively reduces vibration during the grinding process, avoids the impact of vibration on processing accuracy, and ensures that each tooth of the saw blade is ground evenly, achieving high-precision processing effects stably.

2.2 180° Free Rotation of Front & Rear Angles

The core advantage of the MF128 lies in the 180° free rotation function of the front and rear angles. During the grinding process, there is no need to replace the grinding wheel when adjusting angles, which greatly shortens the equipment adjustment time, reduces manual operation steps, and significantly improves the overall grinding efficiency.

2.3 Wide Processing Range Up to 800mm

Equipped with a large-size processing platform, the MF128 has a wide processing range and can easily handle various types of circular saw blades within 800mm. It covers most of the common saw blade specifications in industrial production, meeting the diversified processing needs of enterprises without additional equipment investment.

Technical Advantages: Dual Functions & Stable Performance of MF128 Grinding Machine

The excellent performance of the MF128 is supported by mature technical advantages. From structural design to functional integration, every detail is optimized to ensure stable operation, high precision, and strong practicality, bringing long-term value to users.

3.1 Dual Functions of Grinding & Tooth Opening

Different from single-function sharpening equipment, the MF128 integrates dual functions of grinding and tooth opening. It can not only sharpen dull brazed teeth saw blades to restore their cutting performance but also complete tooth opening processing for new saw blades, meeting the dual needs of saw blade repair and new piece processing, and simplifying the production process.

3.2 Low Vibration & High Machining Accuracy

The horizontal spindle layout and transverse grinding design work together to minimize vibration during the operation of the MF128. Low vibration not only ensures the machining accuracy of the saw blade but also reduces wear on the equipment itself, extending the service life of the machine and reducing maintenance costs.

3.3 Efficient Operation with Minimal Adjustment Time

Thanks to the 180° free rotation of the front and rear angles and no need for grinding wheel replacement, the MF128 significantly reduces the adjustment time between different processing procedures. Compared with traditional equipment, it can improve grinding efficiency by 30% or more, helping enterprises save time costs and increase production capacity.

Applications: MF128 Saw Sharpening Machine for Industrial Production Scenarios

With its multi-functional advantages and stable performance, the MF128 is widely used in various industrial scenarios that rely on brazed teeth circular saw blades, providing comprehensive saw blade processing solutions for enterprises and optimizing production efficiency.

4.1 Ideal for Woodworking Saw Blade Processing

In woodworking production, the smoothness of saw blade cutting directly affects the quality of wood products. The MF128 can precisely grind and open teeth for woodworking brazed teeth saw blades, ensuring that the cut surface is flat and free of burrs, and improving the qualification rate of wood products.

4.2 Suitable for Metalworking Saw Blade Repair & Processing

Metalworking saw blades are prone to wear and dulling due to contact with high-hardness materials. The MF128’s precise grinding function can effectively restore the cutting performance of worn metalworking saw blades, while the tooth opening function meets the processing needs of new metal saw blades, reducing the frequency of saw blade replacement.

4.3 Perfect for Polymer & Plastic Processing Saw Blades

Polymer and plastic materials have special physical properties, requiring saw blades to have high sharpness and precise tooth profiles. The MF128’s dual functions of grinding and tooth opening can customize processing according to the characteristics of such materials, ensuring smooth cutting of polymer and plastic materials and avoiding material deformation.

Price & Suppliers: MF128 Industrial Circular Blade Sharpening Machine for Sale

As a professional manufacturer of circular saw blade grinding equipment, we focus on providing high-quality and cost-effective solutions for enterprises. The MF128 semi-automatic circular saw blade grinding machine integrates multiple advantages, making it a cost-effective choice for industrial production.

5.1 MF128 Circular Blade Sharpening Machine Price & Quotation

The price of the MF128 circular saw blade grinding machine is determined according to configuration and order quantity. We provide personalized quotation schemes for different customer needs, ensuring that customers get high-quality equipment at a reasonable price. For detailed quotations and configuration plans, please contact our sales team.

5.2 Trusted MF128 Circular Saw Blade Sharpening Machine Manufacturers & Suppliers

We have rich experience in the research, development, and production of saw blade grinding equipment. The MF128 has passed strict quality inspection before leaving the factory, with reliable performance and stable quality. We provide one-stop services from equipment sales, installation, and commissioning to after-sales maintenance, solving worries for customers.

5.3 Buy MF128 Semi-Automatic Circular Saw Blade Grinding Machine

Whether you need to repair worn saw blades or process new saw blades, the MF128 is your ideal choice. We support customized configuration adjustments according to your actual production needs, ensuring that the equipment fully matches your workflow. Welcome to contact us to buy or consult the MF128 semi-automatic circular saw blade grinding machine.