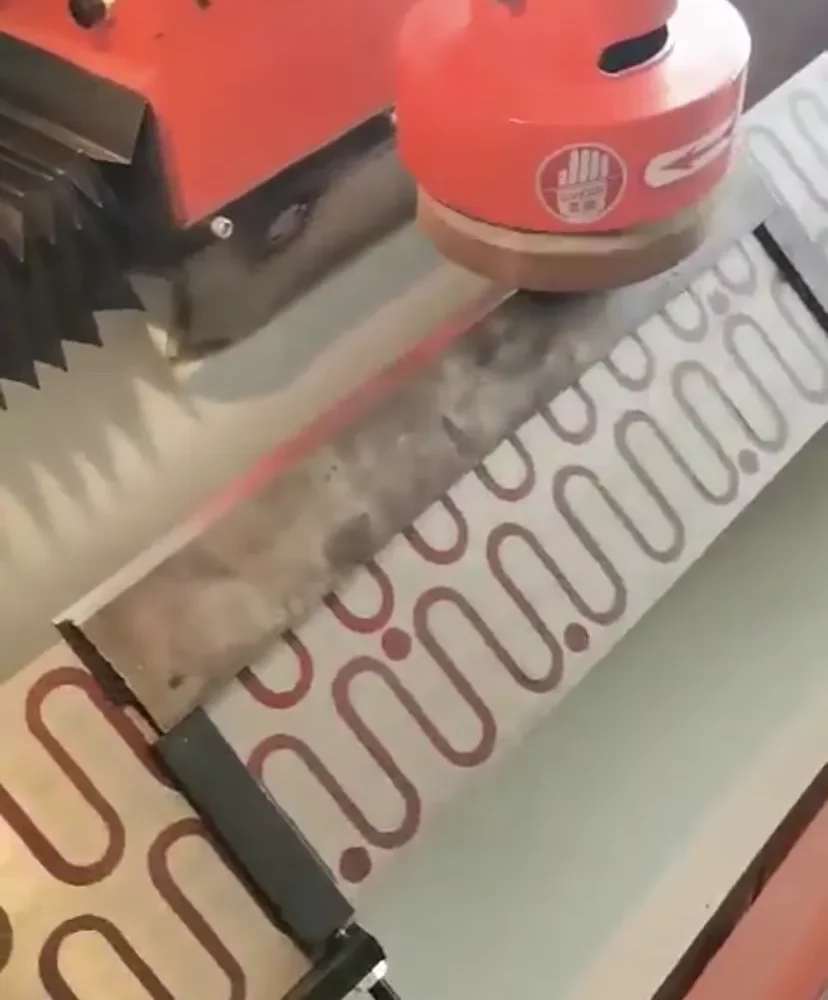

MF2510C-chipper blade sharpening machine

Brief Description

MF2510C Push-button automatic straight knife grinder

Paired with a mechanical tool holder or electromagnetic suction cup fixing device, it can firmly clamp tools of different lengths, even for 1000mm long blade tools, it can be stably fixed to avoid displacement affecting accuracy during grinding.

The equipment is also equipped with a cooling system, which can effectively control the grinding temperature and prevent blade annealing.

The operation adopts a manual feed of the grinding wheel or a variable frequency speed control automatic cutting design, and the cutting speed can be adjusted as needed, balancing the convenience of beginners and the needs of professional processing.

MF2510c linear sharpening machine is suitable for various types of straight knife processing needs below 1000mm.

planer blade sharpening machine The device is easy to operate, and various grinding processes can be completed through buttons without the need for complex debugging.

Specifications

| Item | Value |

|---|---|

| Model | MF2510C |

| Maximum Processing Length, mm | 1000 |

| Maximum Knife Width, mm | 160 |

| Minimum Material Removal per Pass, mm | 0.002 |

| Maximum Material Removal per Pass, mm | 0.01 |

| Grinding Wheel Size, mm | 32×50×150 |

| Grinding Wheel Rotation Speed, rpm | 2830 |

| Coolant Pump Power, W | 40 |

| Feed Motor Power, W | 120 |

| Main Motor Power, kW | 7.5 |

| Overall Dimensions, mm | 3350×1130×1850 |

Structural Features:

Translation

Translation

TOUCH CONTROL PANEL

ELECTROMAGNETIC PLATE

AUTOMATIC LUBRICATION SYSTEM