MF250CNC-carbide circular saw blade sharpener

Brief Description

MF250CNC Abandoned Sharpening Machine is a CNC equipment specially designed for high-precision abandoned tool grinding, for tool alignment

Tailored grinding solution for the blade, compatible with various non-standard shaped blades, including curved and complex curved surfacesBoth blades and customized cutting tools with special angles can achieve precise grinding.

Tailored grinding solution for the blade, compatible with various non-standard shaped blades, including curved and complex curved surfacesBoth blades and customized cutting tools with special angles can achieve precise grinding.

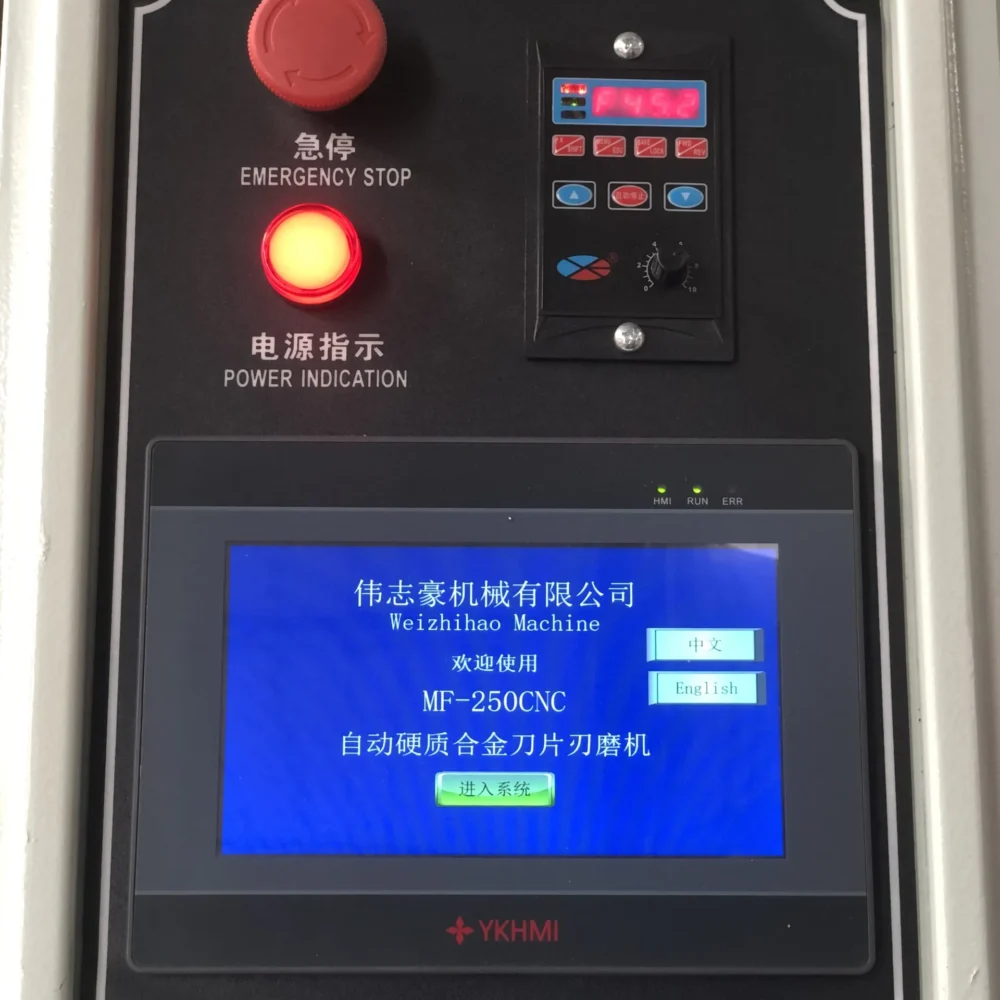

The dedicated grinding head motor it is equipped with can flexibly adjust the axial clearance, and when combined with an intelligent touch screen, it is easy to operate. It can match the optimal grinding parameters according to the hardness and shape of the tool material, and operate intuitively and conveniently. It does not require professional skills and can be quickly mastered. Lightly tap the screen to input tool parameters and select the grinding mode to start the fully automatic grinding process with just one click.

MF250CNC High-Precision Automatic Discardable Alloy Blade Sharpener

The MF250CNC High-Precision Automatic Discardable Alloy Blade Sharpener (also known as an abandoned blade grinding machine) is professional equipment designed for the precision machining field, primarily used for tooth profile grinding and cutting edge finishing of discardable blades and irregular cutting tools.

This machine adopts a collaborative mechanism combining high-speed grinding wheel rotation and workpiece movement, simulating gear meshing trajectories to achieve precise tooth profile machining. Paired with a servo speed control system, it ensures stable operation and consistent machining quality across every blade.

With ultra-high precision grinding capabilities, the MF250CNC controls processing errors within 0.01 thread, meeting the strict tolerance requirements of high-end precision machining applications.

By utilizing a blade pressure plate and knob screw fixed structure—replacing traditional handheld polishing—it completely eliminates the problem of uneven cutting edges, delivering uniform, sharp, and long-lasting cutting performance for each blade.

TYPES OF SHARPENABLE TOOLS:

Machine Videos:

Specifications

| Parameter | Value |

|---|---|

| Model | MF250 CNC |

| Maximum Processing Length, mm | 500 |

| Maximum Processing Width, mm | 100 |

| Maximum Knife Width, mm | 140 |

| Minimum Knife Material Removal per Pass, mm | 0.005 |

| Maximum Knife Material Removal per Pass, mm | 0.01 |

| Grinding Wheel Size, mm | 32×50×150 |

| Grinding Wheel Rotation Speed, rpm | 2,830 |

| Cooling Fluid Feed Pump Power, W | 40 |

| Feed Motor Power, W | 120 |

| Main Motor Power, kW | 1.5 |

| Overall Dimensions, mm | 1150×530×1380 |

CAST BED

The machine tool is manufactured on the basis of a cast bed. Only a cast bed can provide the machine tool with the required rigidity, vibration resistance and reliability, which ensures high precision of tool sharpening.

SPECIAL MAGNETIC PLATE

The special oversize magnetic plate (500×100 mm) is made of high-quality steel and equipped with neodymium cylinders, which allows for securing both profile and flat carbide (HM) cutters.

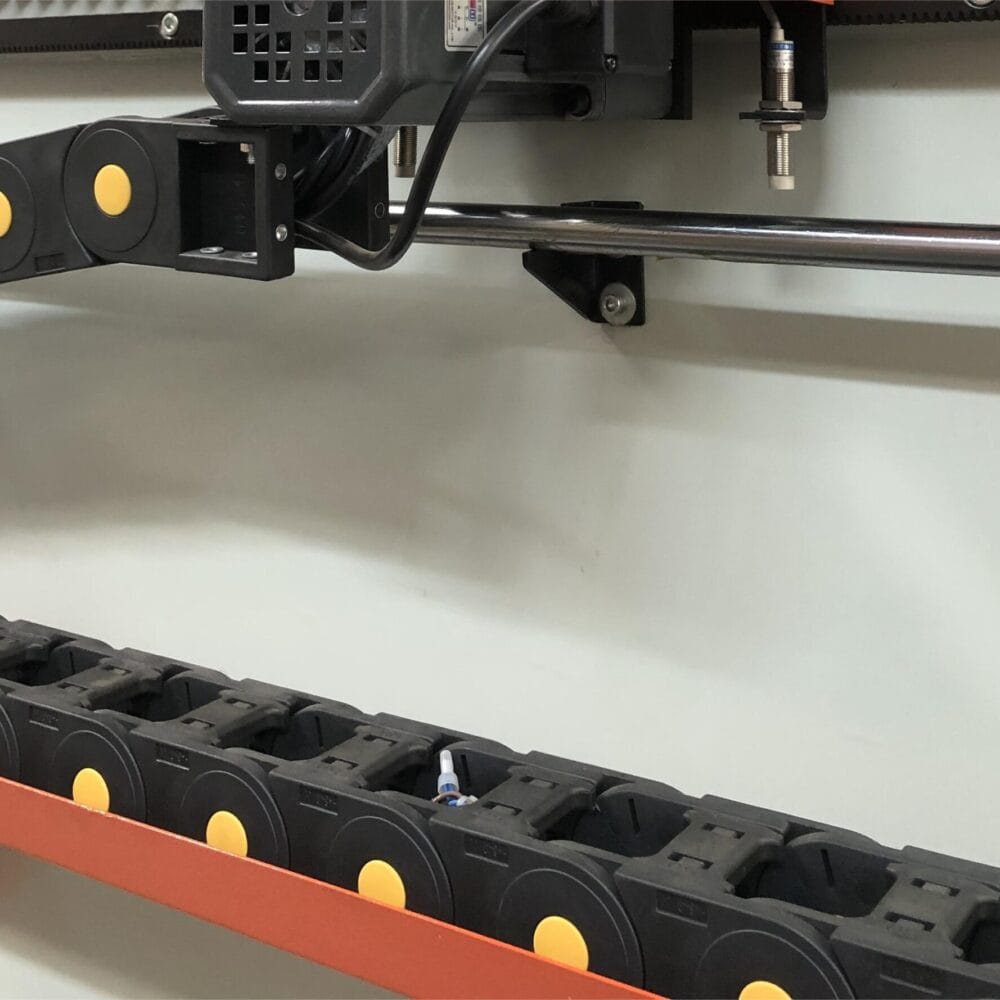

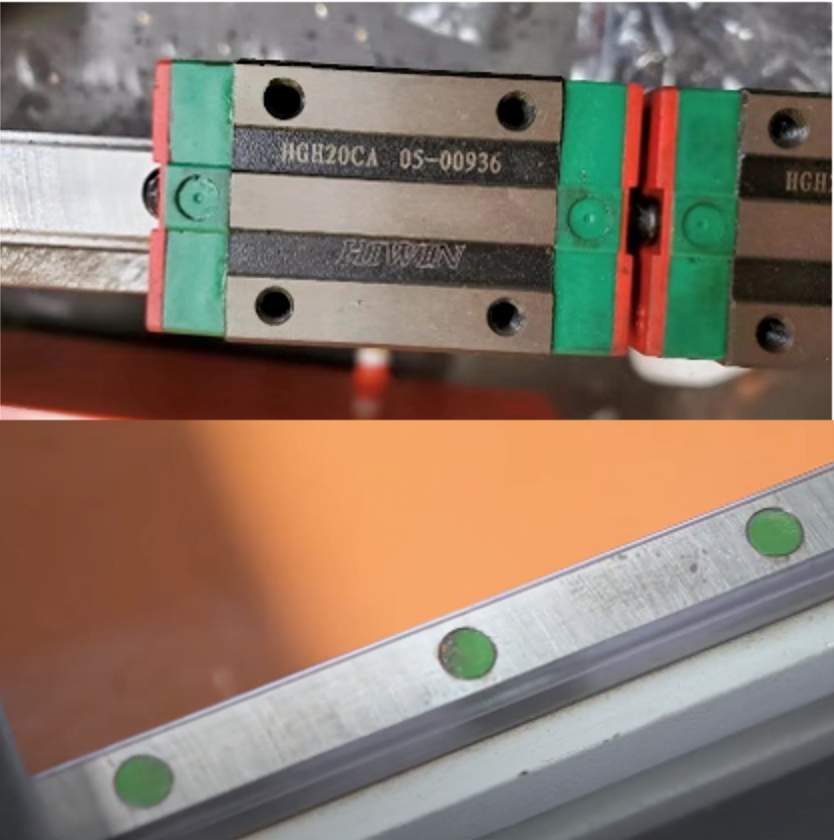

SLIDE REST WITH GRINDING UNIT

The slide rest with grinding unit moves in automatic mode by means of an electric drive. The machine tool adopts HIWIN (Taiwan) linear guides. This ensures the positioning accuracy and smooth movement of the grinding unit during the grinding process.

Automatic Grinding Machine Product Introduction

This fully automatic grinding machine adopts industrial-grade PLC touch screen control, enabling intuitive operation, flexible parameter setting, real-time operation monitoring and high production change efficiency. With full-process automation from loading to unloading, it operates 24/7 continuously via high-precision positioning and servo systems, solving manual operation issues (uneven precision, low efficiency) and boosting productivity & qualification rate significantly.

Featuring adjustable acceleration/deceleration, it adapts to diverse workpieces (different materials/hardness) and grinding processes. With high precision (±0.001mm), stability, comprehensive safety protection and easy maintenance, it widely serves precision grinding needs in hardware, electronics, auto parts and other industries.

The workpiece on the left, after grinding, boasts a smooth and glossy surface with uniform and delicate textures, precise dimensions that fully meet the standard specifications, and burr-free, flawless edges, making it ready for subsequent processing or assembly directly. By contrast, the unground workpiece on the right still retains rough residues from previous processing, with an uneven surface, sharp edges and dimensional deviations, which requires grinding treatment to satisfy the production accuracy requirements.